Independent Proof of Product Performance

The Hohenstein Quality Label is issued for products that have been rigorously tested and meet defined minimum requirements. Testing criteria is based on decades of scientific research and considers practical, real-use situations. All testing is conducted in Hohenstein's accredited testing labs.

Build trust.

The Hohenstein Quality Label extends our credibility to retailers, brands and suppliers for easy recognition of high quality products and verification of product claims.

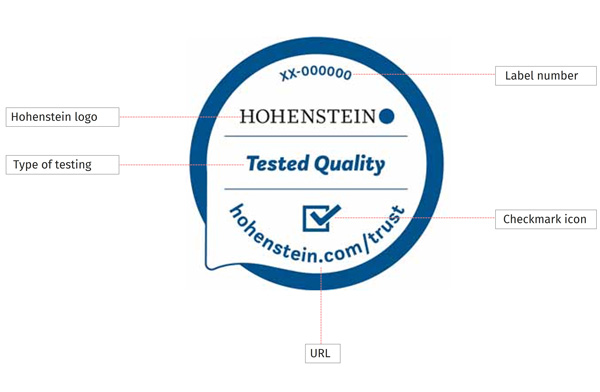

Hohenstein Quality Label Elements:

The Hohenstein Quality Label consists of five basic elements that must always be included. The trusted and traceable label includes certificate number, institute and website. Extended labels are available to include more information. Please view our labeling guide for more detail.