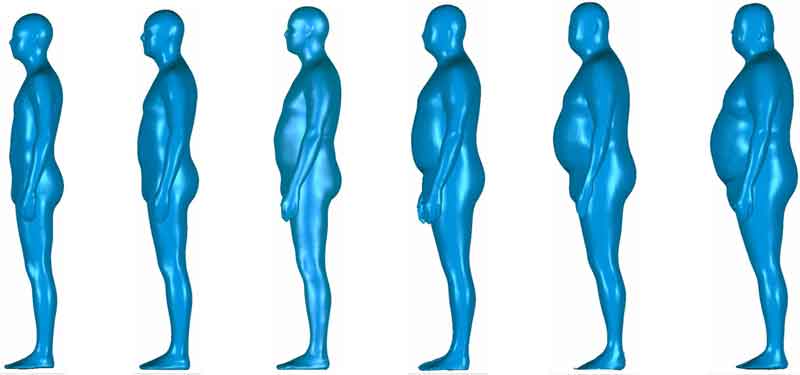

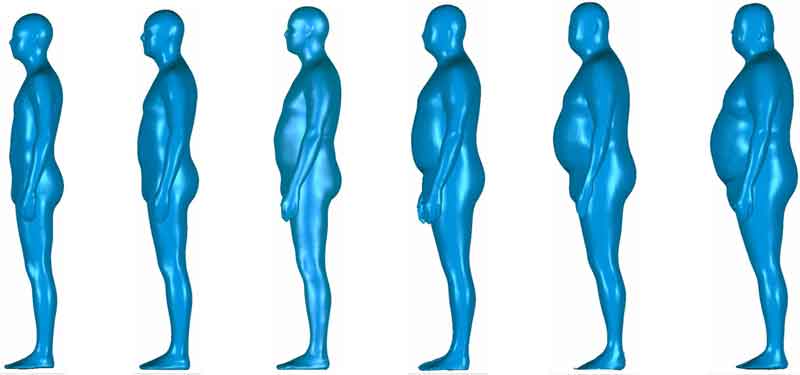

Information based on Hohenstein's huge database of body scans:

- 3D/4D scans and analysis

- Size, shape and demographic data with full body, heads, hands, feet

- Men, women, children, plus sizes, seniors, pregnant women, SizeNorthAmerica, SizeGERMANY

Hohenstein uses deep knowledge of garment construction plus applied research.