All UV protective clothing = PPE

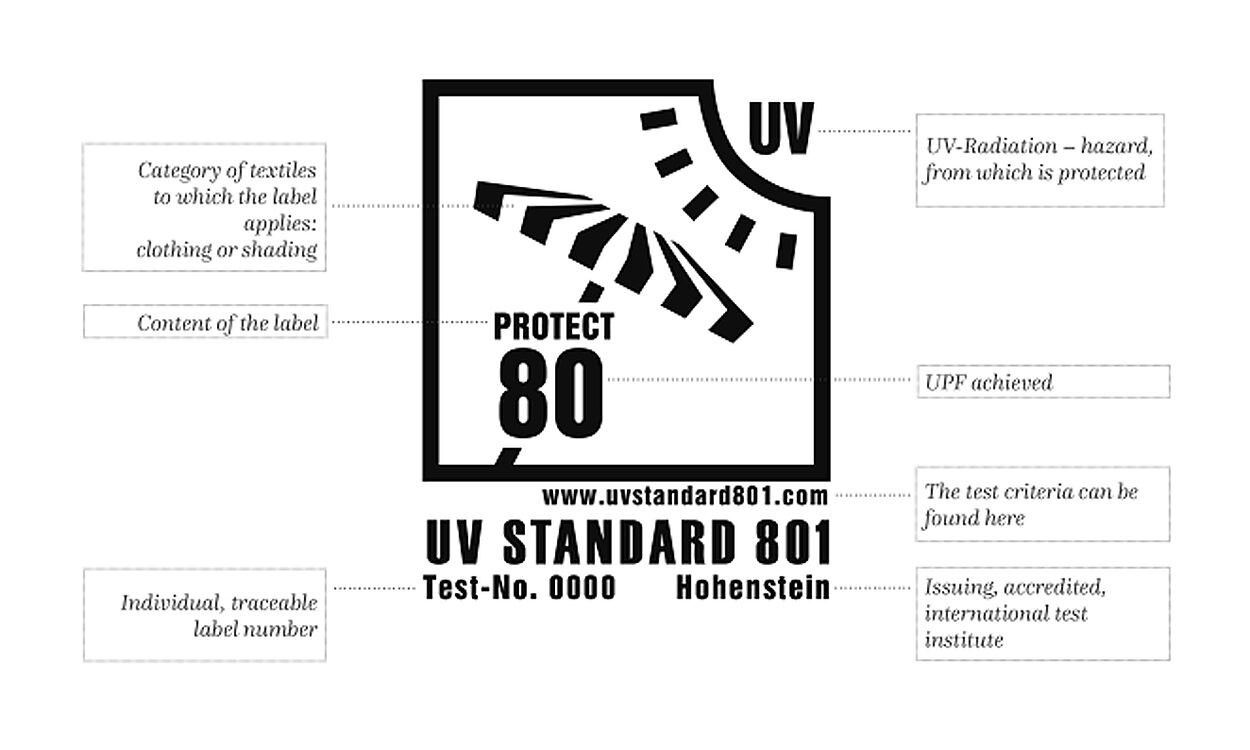

When sold in the EU, any UV protective clothing is considered PPE, which must also carry a CE Mark. UV STANDARD 801 is recognized as a technical specification and necessary proof for UV protective properties.

Hohenstein is also a notified body for compliance with the PPE Directive and CE Marking, which is a separate process from UV STANDARD 801 certification.