Add digital data to physical swatch books.

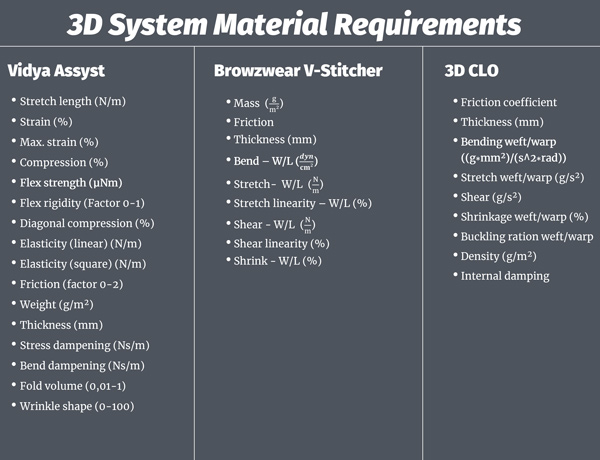

Including digital material parameters in swatch books is becoming as important as composition and weight.

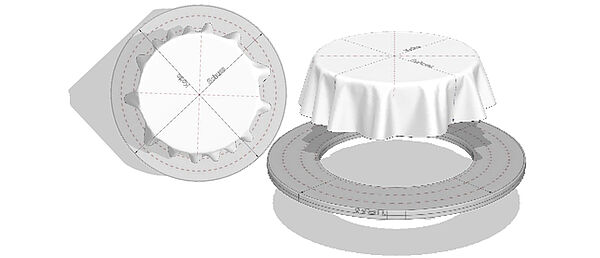

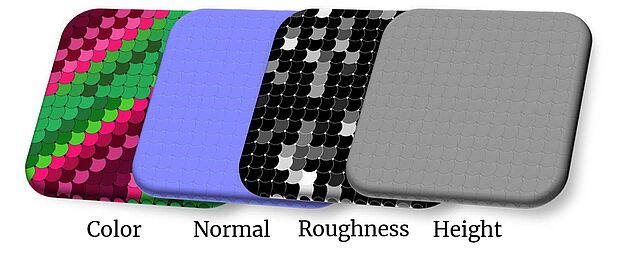

Our swatch book data includes the inputs for specific platforms, allowing designers to see and feel the fabric samples they are using, then accurately design in 3D.

We can either create the data for your own swatch books or produce the books for you.