STANDARD 100 means textiles you can trust.

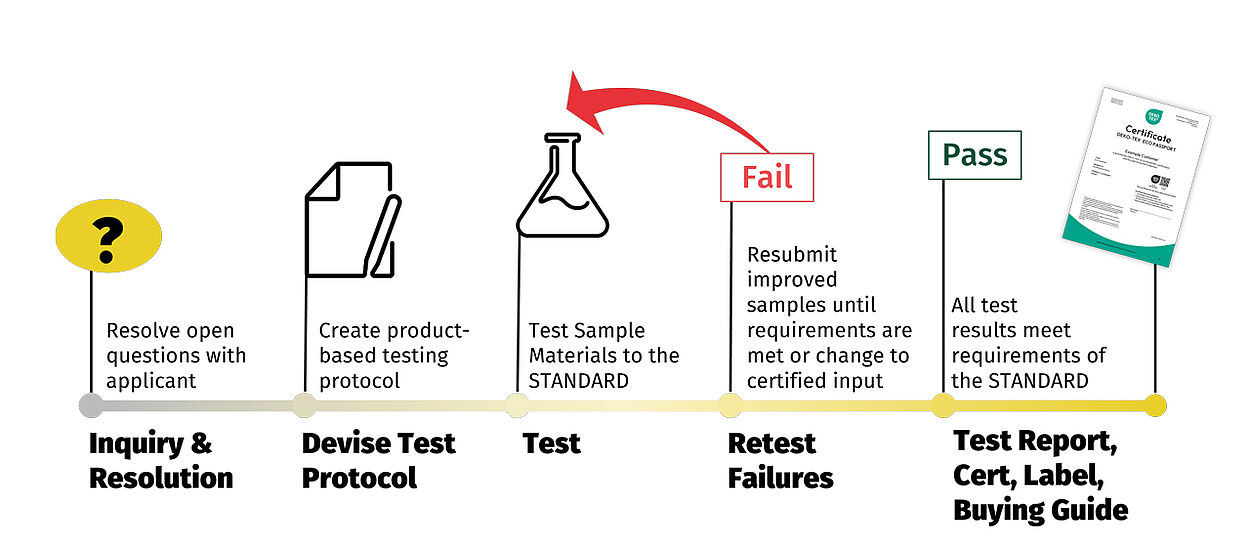

OEKO-TEX® STANDARD 100 is a globally standardized, independent testing and certification system for safer textiles.

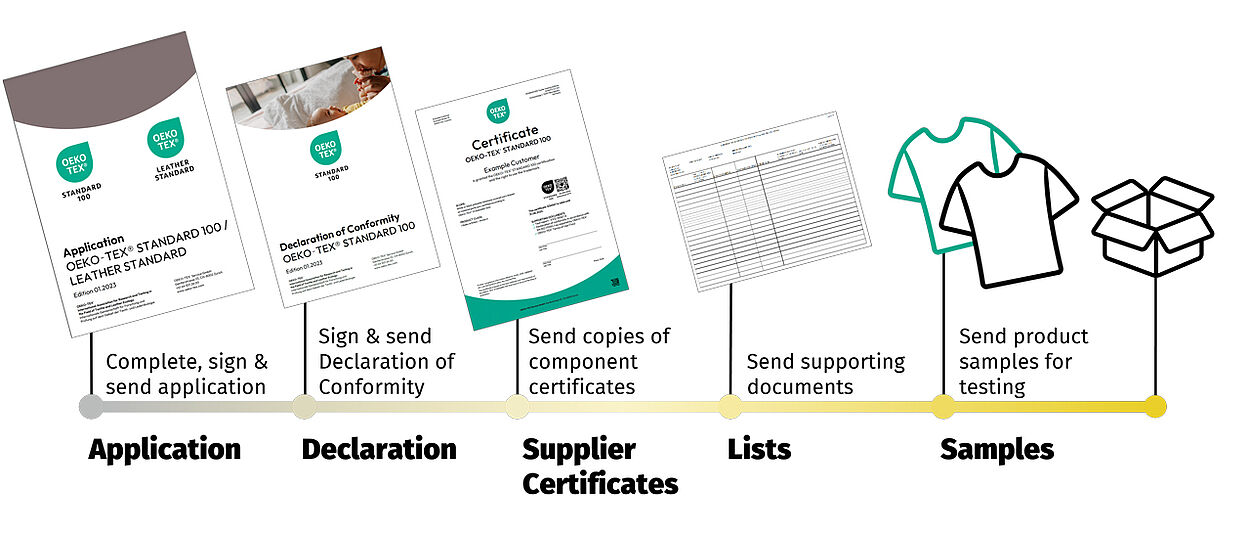

Products that have been successfully tested for harmful substances are awarded the STANDARD 100 label for clear and efficient customer communication. The certificate provides independent verification and reputation protection for B2B partners.

Testing for harmful substances with STANDARD 100 incorporates important legal regulations, numerous chemicals that pose a risk to health (including some that are not yet legally regulated) and a wide variety of health parameters.