U.S. EPR Regulations

Extended Producer Responsibility in the United States

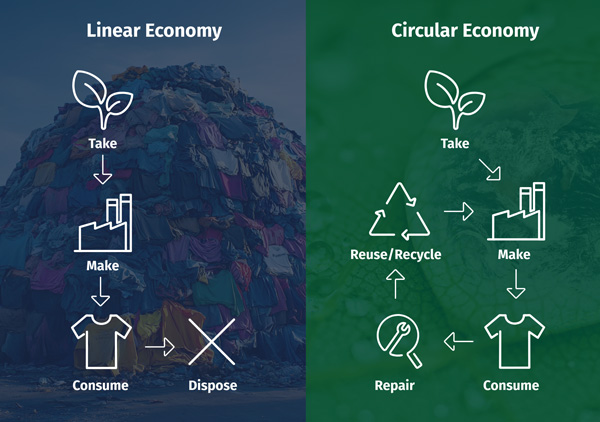

U.S. EPR regulations are defined at the state level, specifying product categories and reporting obligations.

- Textiles

- California 2024 Responsible Textile Recovery Act

- California 2013 Used Mattress Recovery and Recycling Act

- California 2010 Carpet Stewardship Law

- Rhode Island 2013 Responsible Recycling, Reuse and Disposal of Mattresses

- New York 2022 Carpet Collection Program Law

- Oregon 2022 Mattress Stewardship Act

- Medical

- California 2018 Pharmaceutical and Sharps Waste Stewardship Program

- Hardgoods

- Connecticut 2023 Act Concerning Extended Producer Responsibility for Tires

EU EPR Regulations

Extended Producer Responsibility in Europe

In the EU, EPR is governed by directives from the European Commission, with each member implementing national laws.

- Requires brands and retailers to report volumes and pay waste management fees

- Covers apparel, footwear, accessories and home textiles

- Member states will establish national EPR schemes by April 2028

- Companies should prepare data and compliance systems now