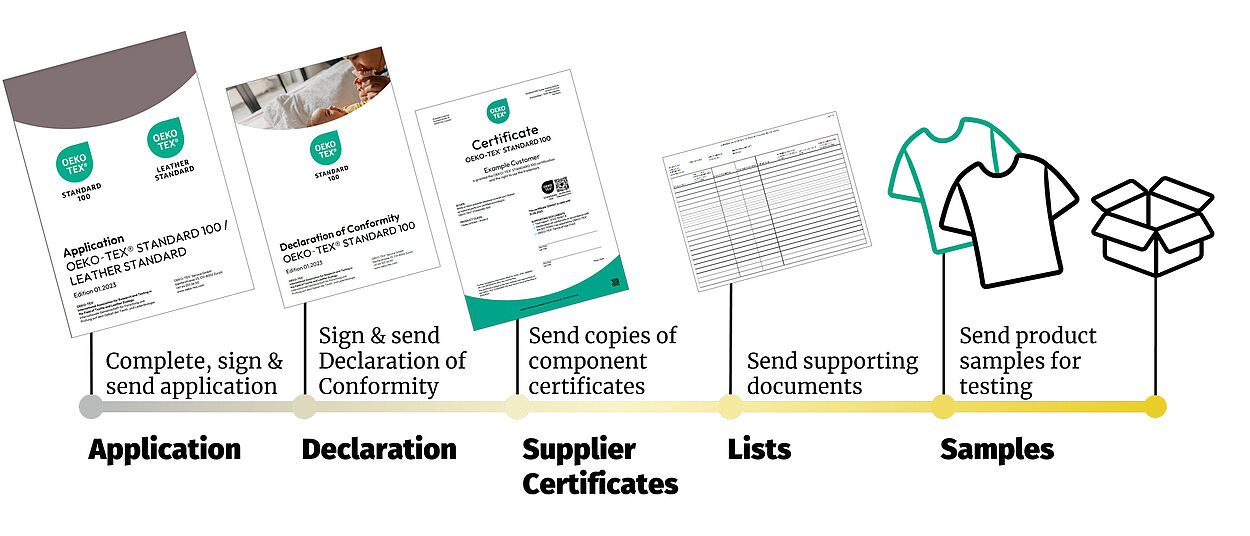

1. Download relevant application and FAQ

Application

FAQ

2. Complete application

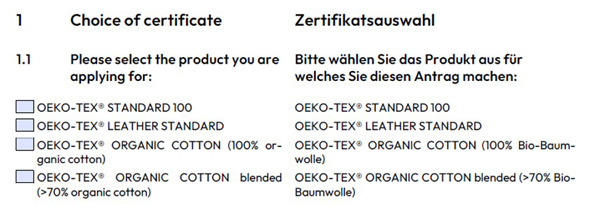

Certification Type (p. 2-3)

1.2 Choose Annex

- Annex 4/5

The parameters & defined limit values are reliable, advised & sensible. They are fixed from a human ecological point of view. - Annex 6/7

The expanded criteria catalogue has been developed especially for companies who are focused on the DETOX campaign.

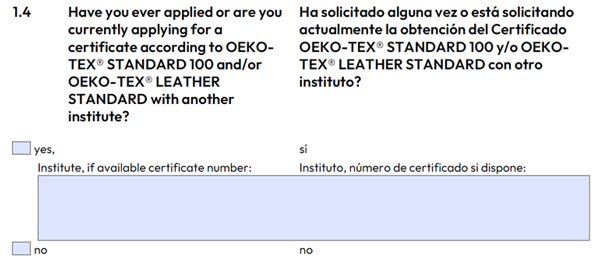

Previous Application and Label Check (p. 4)

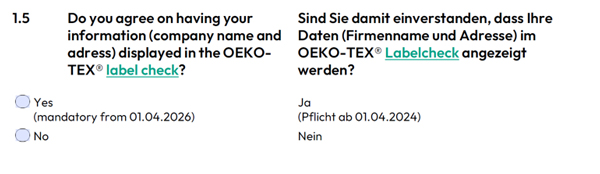

1.5 Label Check Display

Show your company name & address in the OEKO-TEX® Label Check?

- Yes

- No

(Starting 2026, this level of transparency will be required for STANDARD 100 and ORGANIC COTTON certificates.)

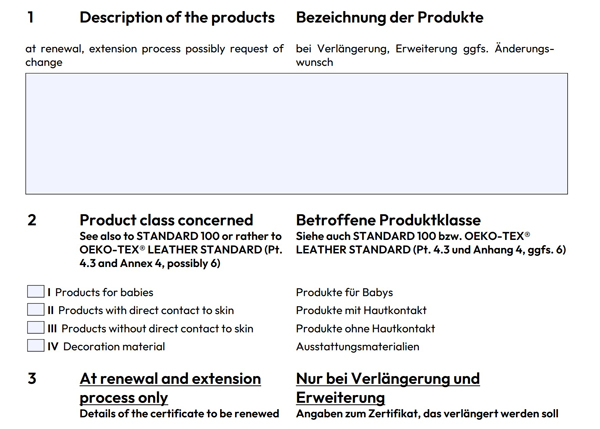

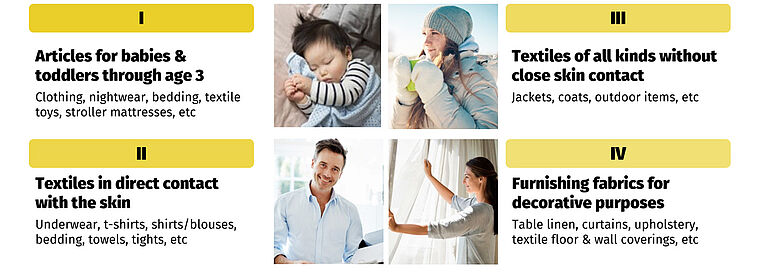

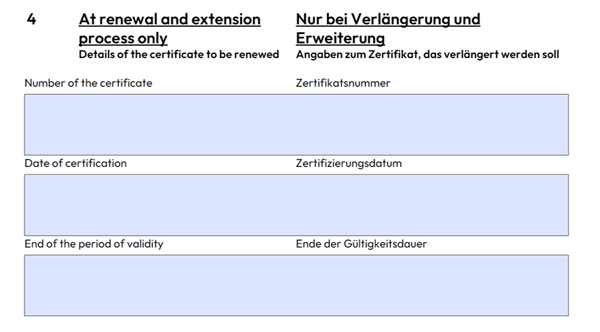

Products + Renewal/Extension (p. 5)

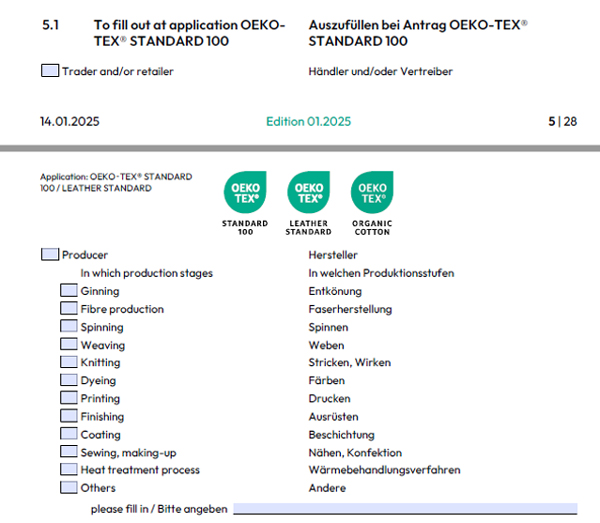

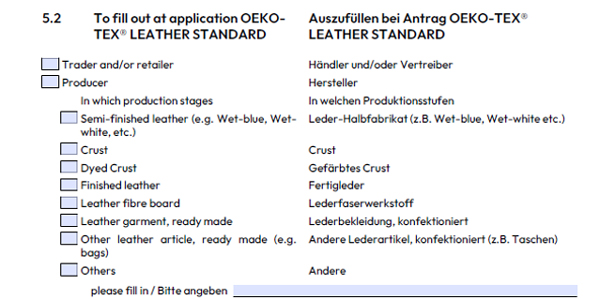

Applicant Business Type (p. 5-6)

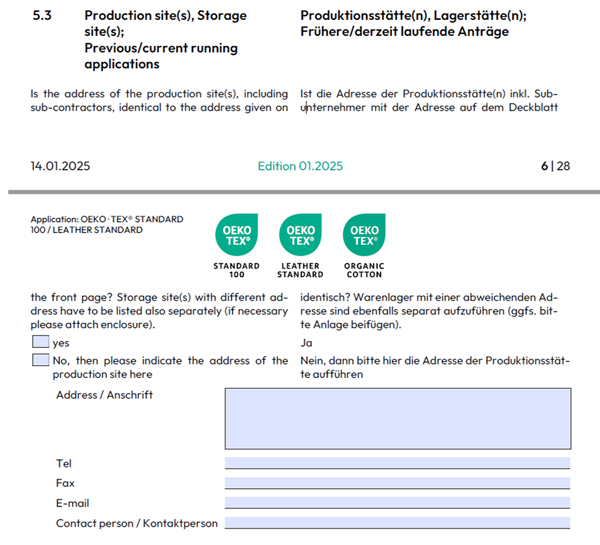

Production Site (p. 6-7)

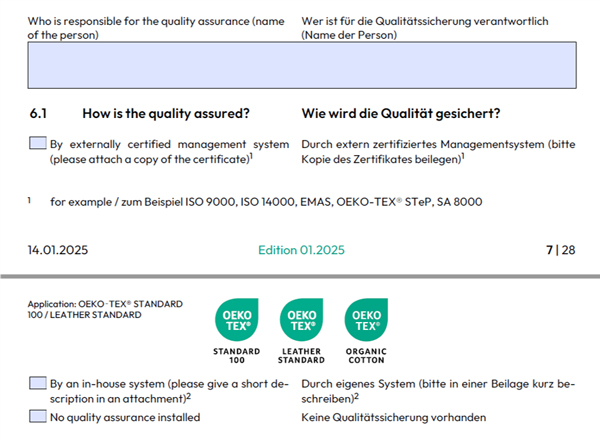

Quality Assurance (p. 7-8)

6 Who?

- Person responsible for quality assurance

6.1 How?

- Attach copies of certificates

- Attach flow chart of quality assurance process

Track these in tab 2 of our supporting documents template.

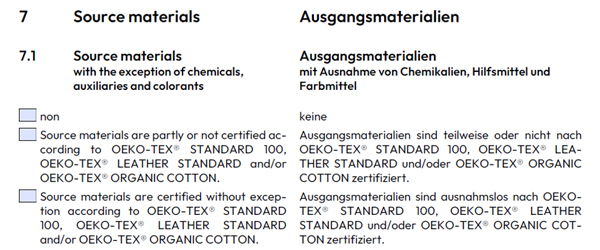

Source Materials (p. 8)

7.1

Are your source materials pre-certified to STANDARD 100 or LEATHER STANDARD?

Check:

- NONE

-or- - SOME

-or- - ALL

You will need to include a list later in the application.

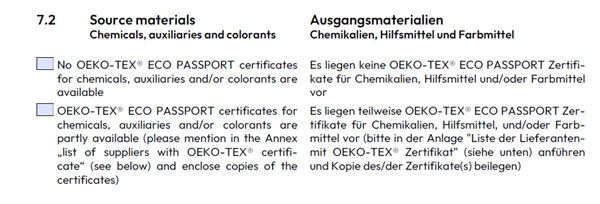

Source Chemicals (p. 9)

7.2

Are your source chemicals pre-certified to ECO PASSPORT?

Check:

- NONE

-or- - ANY (or all)

You will need to include a list later in the application.

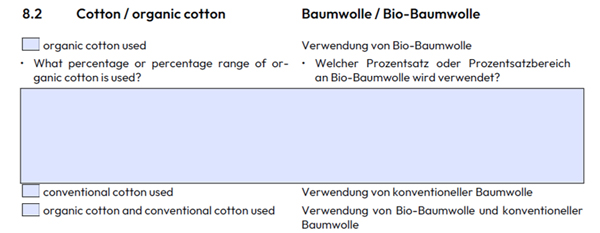

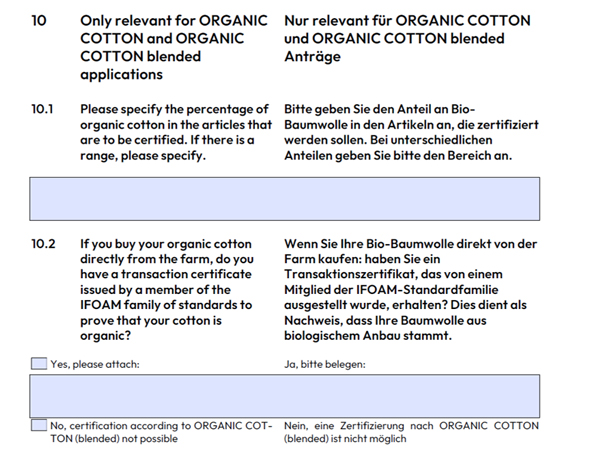

Organic Cotton (p. 9)

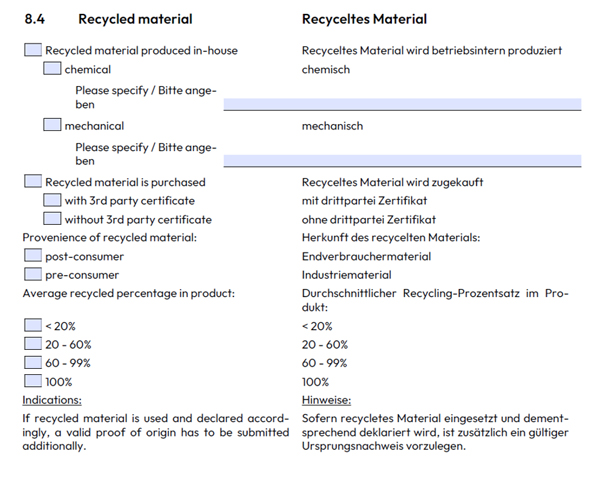

Recycled Material (p. 10)

8.4

Recycled materials must be on a separate application form and certificate from non-recycled materials.

Please submit separate application forms for recycled vs non-recycled materials.

- Check if you produced the recycled material - specify the chemical or mechanical recycling process

- Check if you purchased the recycled material

- Post- vs pre-consumer recycled

- % recycled material in product

*Attach certificate of origin or validation of any recycled material claim.

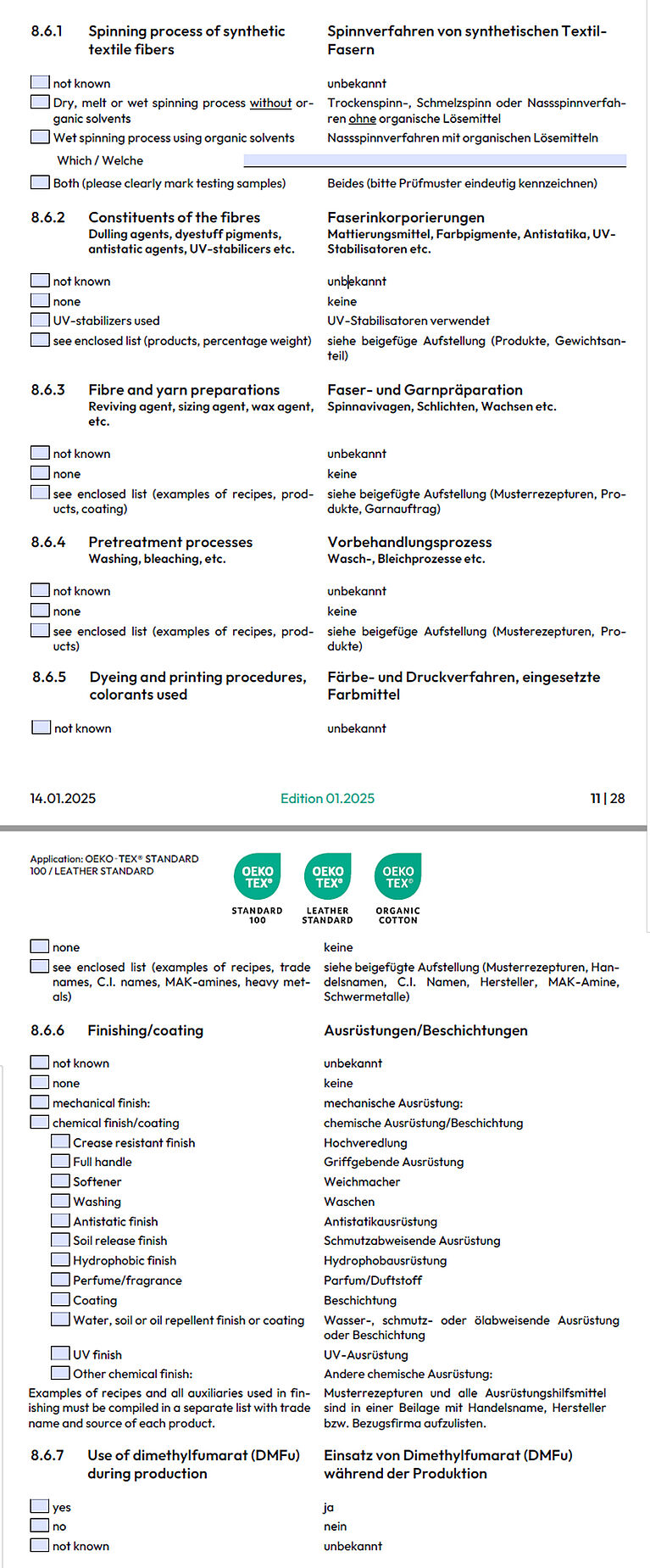

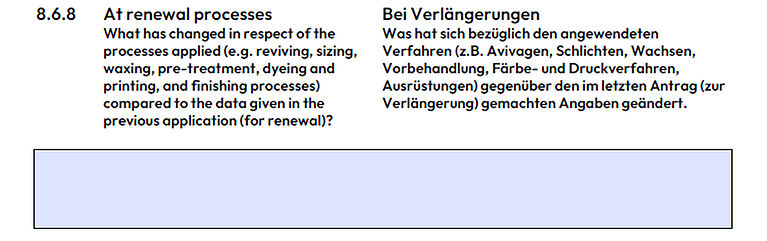

Textile Materials (p. 11-12)

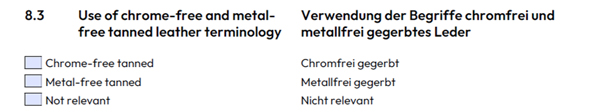

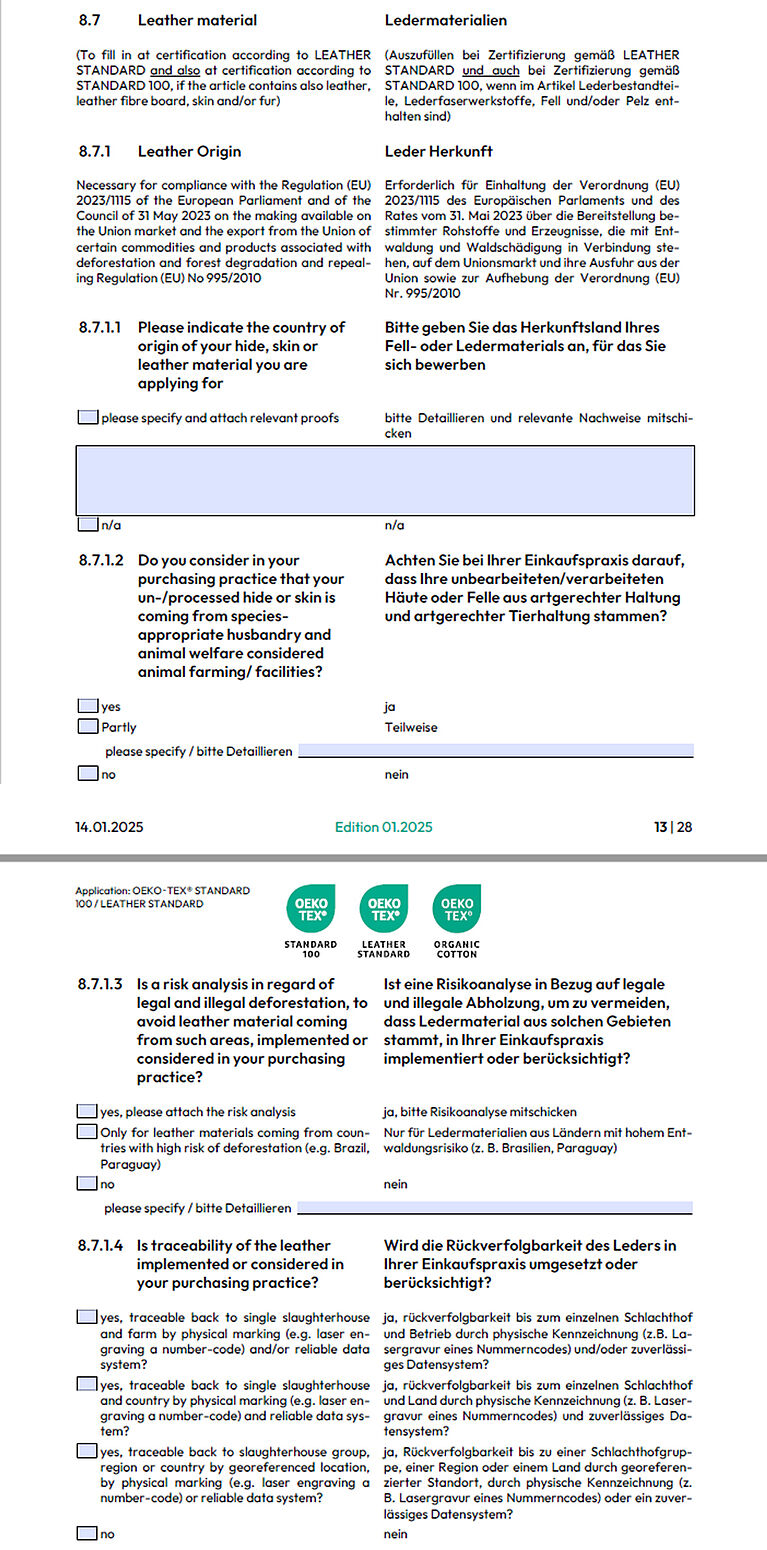

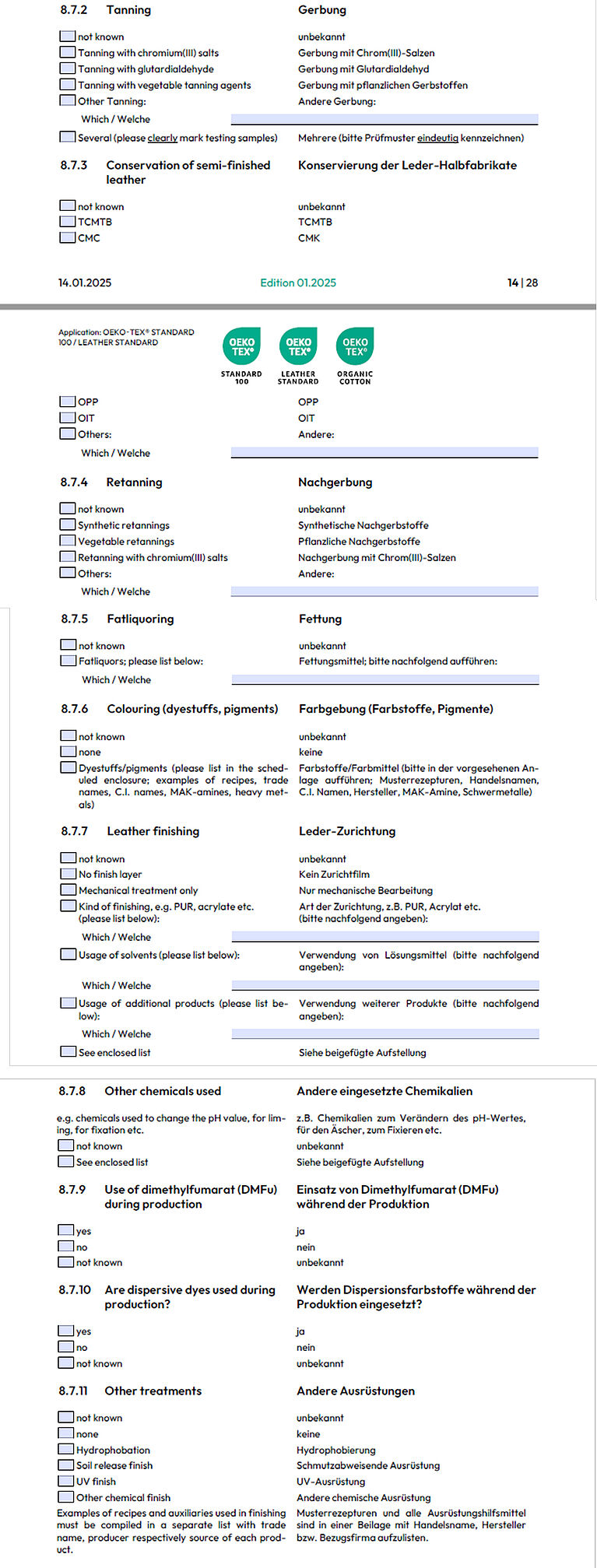

Leather Material (p. 13-16)

Complete this section if product is made of leather or contains leather components (including leather, leather fiber board, skin or fur).

8.7.1.1 – 8.7.1.4 - Leather Origin

- List the country of origin

- Attach proof of origin

- Check N/A if no leather

- Do you consider animal welfare?

- Do you conduct risk analysis for deforestation?

- Traceability with physical marking and reliable data:

- Back to single slaughterhouse/farm

- Back to single slaughterhouse/farm and country

- Back to slaughterhouse group and region/country by geo-preferenced location

- Not traceable

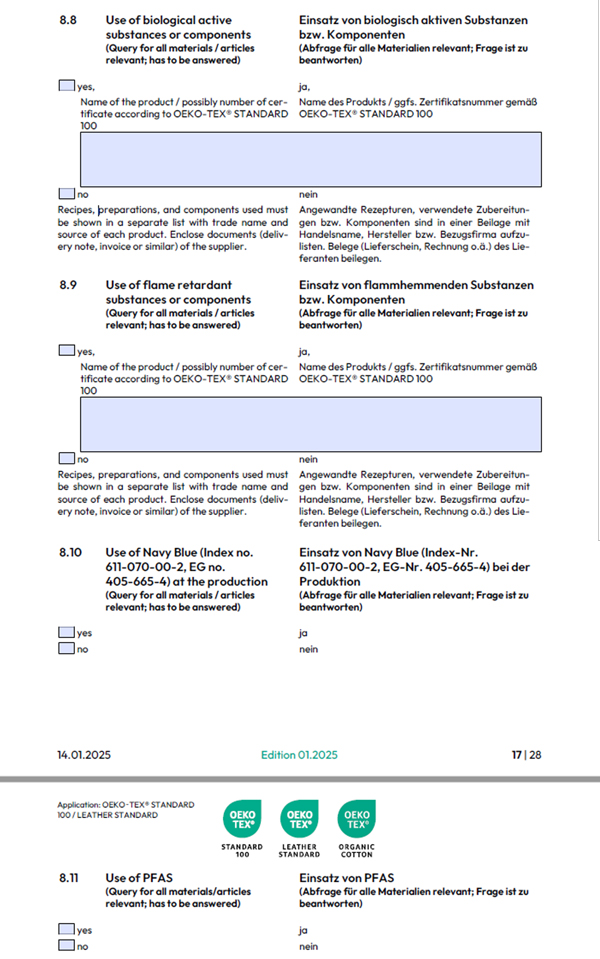

Special Chemicals (p. 17-18)

Other Materials & Treatments (p. 18)

Resellers (p. 18-19)

9

Skip section if manufacturer - only complete if buying product to resell without further processing

9.1

Number of suppliers

9.2

You will include a list of suppliers later in the application.

For OEKO-TEX® ORGANIC COTTON Certification Only (p. 19)

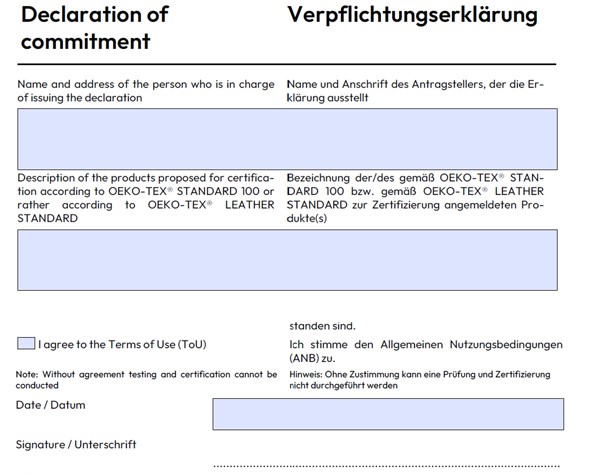

Commitment (p. 20-21)

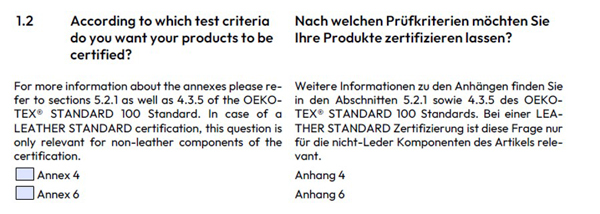

- COMPANY Name + Address

- Product description: Copy/paste answer from section 1

- Agree to Terms of Use

- Don’t forget to sign and date!

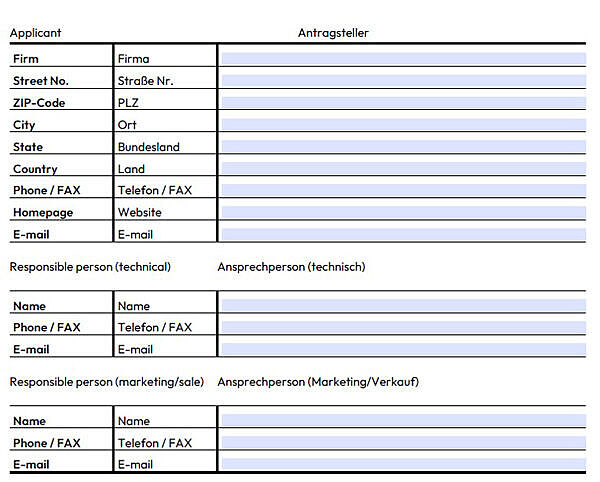

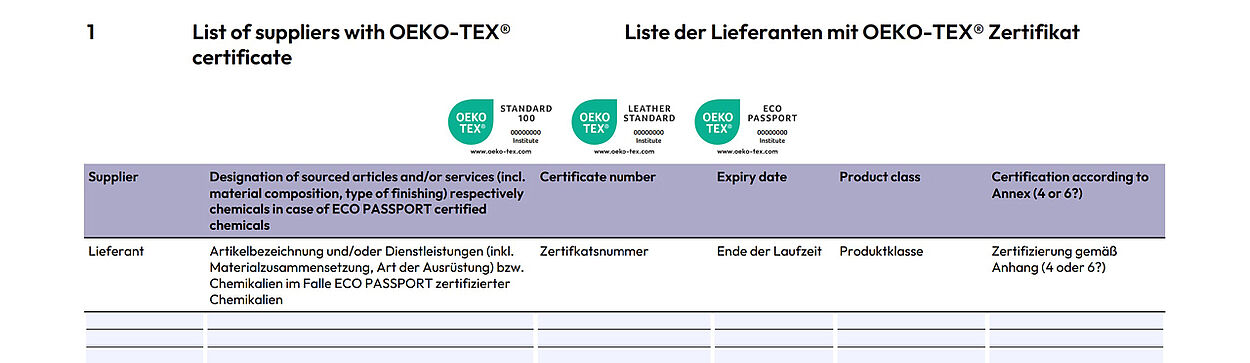

List: OEKO-TEX® Pre-certified Materials & Chemicals (p.22)

- Enclose a copy of each OEKO-TEX® certificate with your application

- Enclose proof of business relationship with the supplier (e.g. invoice, delivery slip, etc.)

This list is tab 3 in our supporting documents template.

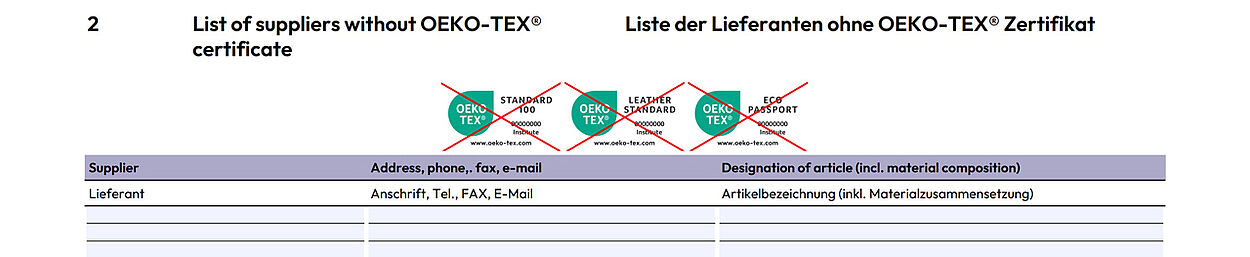

List: Materials & Chemicals with NO OEKO-TEX® Certificate (p. 23)

This list is tab 4 in our supporting documents template.

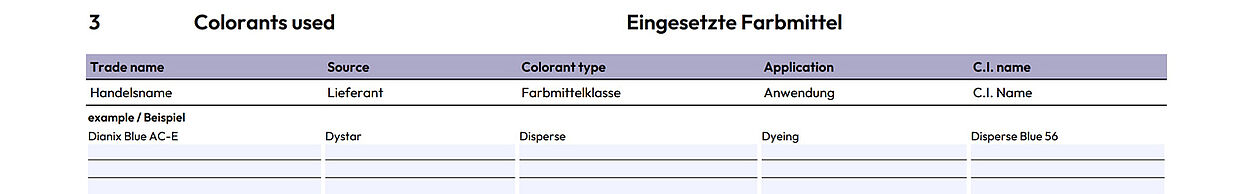

List: Dyestuffs & Colorants Used (p. 24)

This list is tab 5 in our supporting documents template.

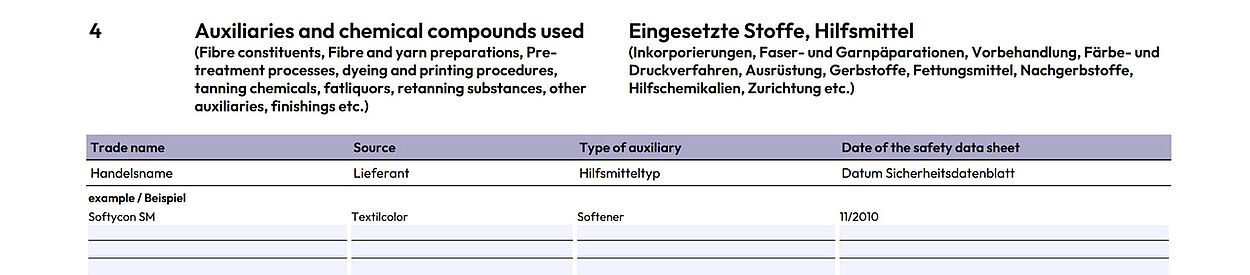

Optional: List Non-dyestuff Chemicals & Auxiliaries (p. 25)

More detail = lower testing cost

This list is tab 6 in our supporting documents template.

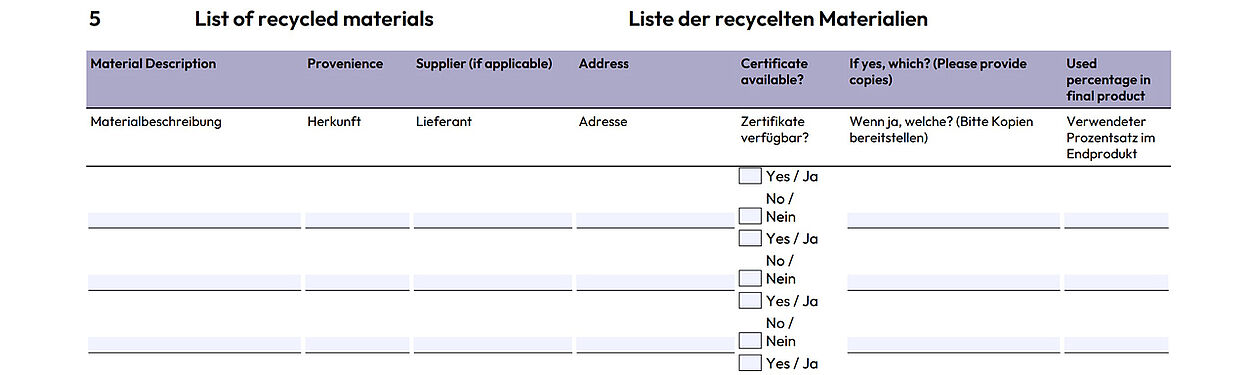

List: Recycled Materials (p. 26-27)

This list is tab 7 in our supporting documents template.

3. Complete Declaration of Conformity

- Company name and address must match certificate

- If there is a change from previous application, send new legal documents (W2, etc)

- Include personal name and company name

- Must select annex (matching application)

- If there are changes between application submission and completion, a new declaration is required

Download the applicable document.

STANDARD 100

LEATHER STANDARD

ORGANIC COTTON

4. Gather supporting documents

Include copies of supplier certificates (STANDARD 100, LEATHER STANDARD, ECO PASSPORT).

Send proof of quality assurance and external certificates.

Proof of quality assurance and management must include:

- Organizational chart/list with names and responsibilities (CEO, purchasing, QM etc.)

- Documented standard operating procedures for the purchase (suppliers), production, traceability, quality control (incoming and outgoing), proper storage and identification (of raw materials as well as products that may or may not be covered by the OEKO-TEX® certification)

- Documented standard operating procedure on how to handle non-conformities and corrective actions

Recycled Materials

- Complete details in the supporting documents spreadsheet - Recycled Materials tab

- Include certificate(s) of origin for each recycled material

Organic Materials

- Include traceability certificates

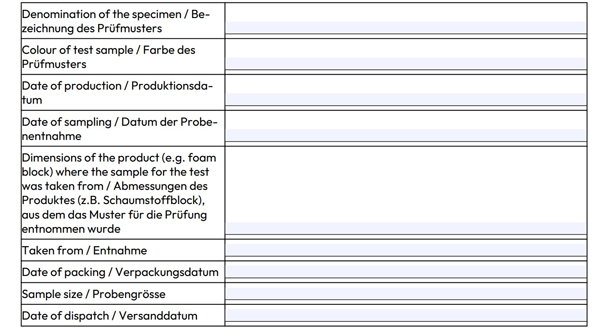

5. Collect samples for testing

Sample Instructions

Submit material samples, including:

- All types of pre-treatment, finishing and coloration processes

- All dye classes and dyestuffs evenly distributed in maximum concentration

- Samples in red, yellow, green, blue, black, white, orange and purple

- Max 5 dyestuffs per sample

- Samples in each fluorescent color to be tested separately

- All printing dyestuffs in maximum concentration:

- Solid printed color swatch: 12” x 12” (30 x 30 cm)

- One block print per dyestuff, five samples from current production for each printing process

- Screenprints, heat transfer, sublimation, direct, etc.

- 12” x 12” full coverage drawdowns of red, yellow, green, blue, black, white, orange and purple

- Submit a collection of printed samples that will cover red, yellow, green, blue, black, white, orange and purple in pattern

6. Ship to Hohenstein

Include:

- Completed and signed application

- Signed Declaration of Conformity

- Supplier certificates (with relationship proof) and supporting documents (electronic versions preferred)

Optional: Also print and staple supplier certificates to the specific sample - Samples

-Processing can NOT begin until all samples are received

-Shipping all samples together speeds the process

Packaging:

Test sample packaging must satisfy specific quality requirements in order to protect the samples and guarantee accurate, reproducible and meaningful test results.

- Test samples must be packed individually in tear resistant polyethylene film or polyethylene bags, to avoid contamination during transport

- The samples should be wrapped twice and sealed with adhesive tape

- The packed bags must be properly labeled for identification with sample numbers, material, supplier, receipts, etc.

- Packing test samples solely in cardboard boxes and/or paper is strictly prohibited

- Whether shipping from separate locations, direct from suppliers or in one box: please ensure all samples are clearly and correctly labeled so that they can be matched with your application

Ship:

- For US/CANADA/MEXICO/HONDURAS/GUATEMALA customers:

Hohenstein Institute America

304 Sroufe Street

Ligonier, IN 46767

USA

+1 800 731 9468 - For other AMERICAS customers:

Hohenstein Laboratories GmbH & Co. KG

Schlosssteige 1

74357 Boennigheim

GERMANY

+49 7143 271-0 - For all OTHER customers:

Please check with your local Hohenstein contact.

Email:

- In addition to including them with the shipment, please email the documents to your main Hohenstein America contact

- Your company's W9 form

- Any vendor forms required for your company to process payments

Avoid Delays:

- Provide clear, detailed information in the application & supporting documents – what are you making, how are you making it, and what is it made of?

- Respond to inquiries in a timely manner – if there are questions or things that need clarification during the review process, respond as soon as you’re able

- Be prepared to pay once the invoice is issued – payment in advance of testing is required for the first certification

- Clearly label samples. Consolidate shipments if possible

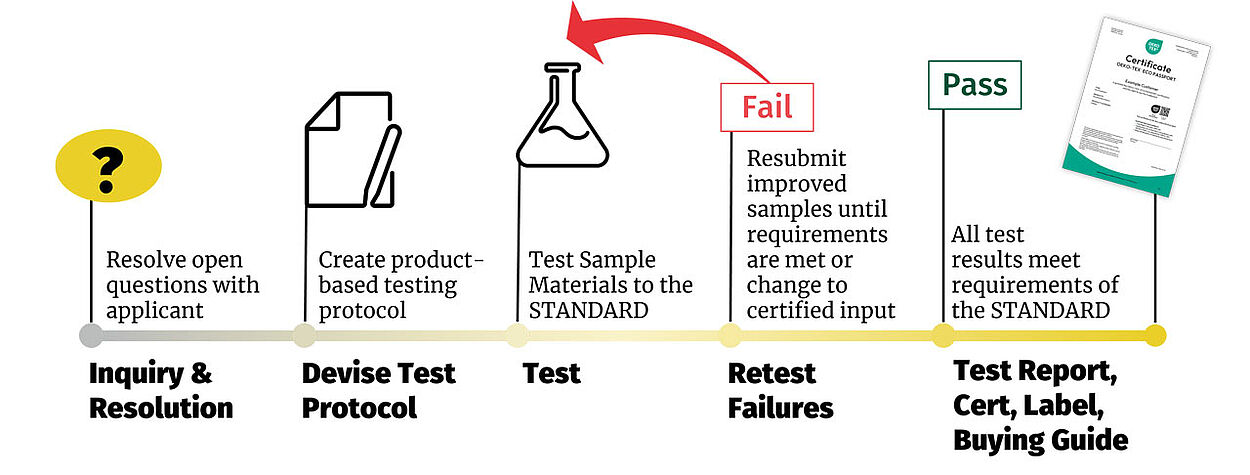

Evaluation Steps

7. Plan and pricing

Hohenstein team:

- Reviews the information and follows up with questions on any open items

- Creates a testing plan

- Provides the price for the certification

- Ships the samples to our lab in Germany (for US customers)

8. Testing at Hohenstein lab in Germany

Testing takes ~2 weeks once shipment goes through customs.

9. Certificate and Label issued for 1 year

10. Quality assurance meeting (on-site visit)

After the certificate is issued, we will schedule an on-site visit of your facility to complete the certification process.

To ensure:

- Application matches reality

- Quality assurance system is in place

- Knowledge of certificate benefits cost reduction opportunities

When:

- For STANDARD 100 and LEATHER STANDARD:

- Within 1 year of certificate

- Every 3rd year thereafter

- For ORGANIC COTTON:

- Every year

- Before the certificate is issued